Second, the flow of gas is driven by pressure gradient with the only possible direction of flow being that from a higher to a lower pressure. First, pressure is a scalar quantity, not a vector quantity, and has no direction.

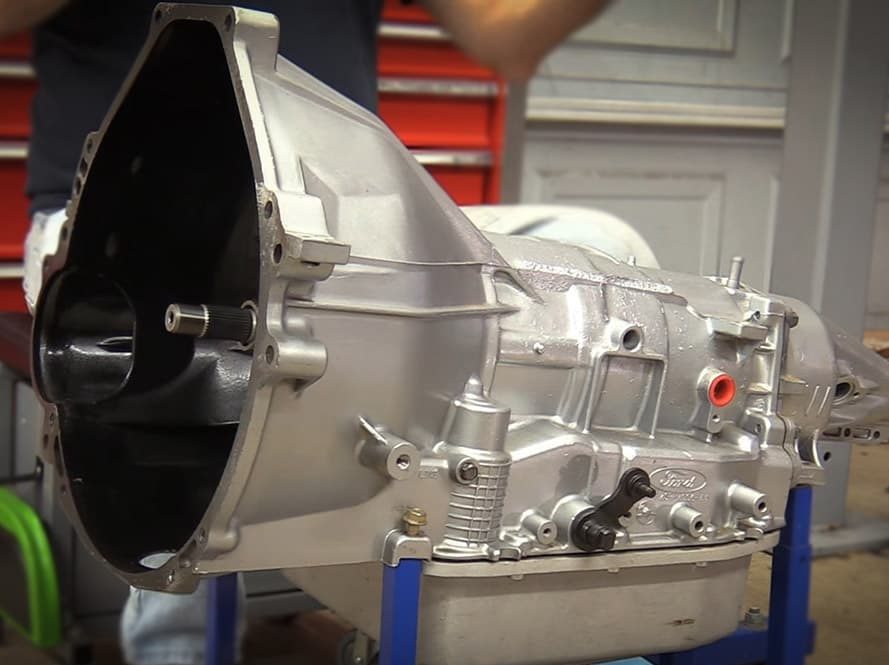

The word back seems to suggest a pressure that is exerted on a fluid against its direction of flow-indeed, back pressure definitions of that sort are common in sources of relaxed scientific standards. It should be noted that the term “back pressure” is counter-intuitive and may interfere with a proper understanding of the exhaust gas flow mechanics. The term back pressure can be also spelled as one word (backpressure) or using a hyphen (back-pressure). For this discussion, the exhaust back pressure is the gage pressure in the exhaust system at the outlet of the exhaust turbine in turbocharged engines or the pressure at the outlet of the exhaust manifold in naturally aspirated engines. Effect on Emissions and Fuel ConsumptionĮngine exhaust back pressure is defined as the exhaust gas pressure that is produced by the engine to overcome the hydraulic resistance of the exhaust system in order to discharge the gases into the atmosphere.Increased back pressure levels can cause increased emissions, increased fuel consumption, and can negatively affect engine performance. Step 7.Abstract: Exhaust system components such as mufflers and exhaust aftertreatment devices are a source of engine exhaust back pressure. If no problem are found, replace the Oil Pump Solenoid. YES, verify that there is good pin to terminal contact in the Oil Pump Solenoid and Powertraint Control Module connectors. Is the test light illuminated and bright during the actuation and was it off when required ? Compare the brightness to that of a direct connection to the battery. The test light should be illuminated and bright. With the scan tool, actuate the Oil Pump Solenoid control to the ON (100%) position. The test light should be off except for a brief period immediately after turning the ignition on. Reconnect the PCM C2 harness connector, turn the ignition on, using a 12 volt test light connected to ground, probe the Oil Pump Selenoid control circuit at the Oil Pump Selenoid harness connector. NO, repair the Oil Pump Solenoid ground control circuit for an open high resistance. Measure the resistance between ground and the Oil Pump solenoid ground circuit at the Oil Pump solenoid harness connector. Check the Oil Pump solenoid ground circuit

-637347259215406087.png)

NO, repair the Oil Pump Solenoid control circuit for an open high resistance. Measure the resistance of the Oil Pump Solenoid control circuit between the oil pump solenoid harness connector. Probimg the PCM harness connector will damage the PCM terminal resulting in poor terminal to pin connection. Check the Oil Pump Solenoid control circuit for an open/high resistanceĬaution : Do not probe the PCM harness connector.

YES , repair the Oil Pump Solenoid control circuit for a short to ground. Is there continuity between ground and the Oil Pump Solenoid control circuit ? Turn the ignition off, disconnect the PCM C2 harness connector, check for continuity between ground and the Oil Pump Solenoid control circuit at the oil pump solenoid harness connector. Check the Oil Pump solenoid control circuit for a short a short to ground YES, repair the Oil Pump solenoid control circuit for a short to voltage. Measure the voltage on the Oil Pump Solenoid control circuit at the Oil Pump selenoid harness connector. There should no voltage present except for a brief period immediately after turning the ignition on. Turn the ignition off, disconnect the Oil Pump Solenoid harness connector. Check the oil pump control circuit for a short to voltage NO, perform the PCM intermittent condition.

0 kommentar(er)

0 kommentar(er)